Phone: 1300 934 471

Service, Maintenance & Repairs

Serviced Equipment is a leading provider of preventative maintenance and breakdown repair services for a wide range of materials handling equipment.

Materials handling equipment repairs—Australia-wide

We service a wide range of industries Australia-wide. All of the work is done by us, so you can be assured that your equipment will be looked after from start to finish. Your business will continue to get the most out of your materials handling equipment, all with minimal downtime.

Contact usElectromechanical repairs

Serviced Equipment specialise in servicing electromechanical equipment (plant items) across a broad spectrum of downstream industries.

Our highly skilled and experienced technicians have the ability to inspect, diagnose and repair almost any fault with an electromechanical machine.

Keep your materials handling equipment performing well, and prevent costly downtime.

How we can help

-

Preventative maintenance

-

Diagnosing and fixing electrical, and mechanical faults

-

Reconditioning old materials handling equipment to near-new condition for a fraction of replacement costs

-

Welding, fabrication and assembly

-

Spare parts

Some of the brands we service

-

Staminalift

-

Liftmaster

-

Simpro

-

Steris

-

Fallshaw

-

Taylor-Dunn

-

Veshai

-

Arjo Huntleigh

-

Hill-Rom

-

Horizon

-

Howard Wright

-

Liftcare

-

Linet

-

Prius

-

EBOS

-

Electrodrive

-

Sulo

-

Wrightway

-

Hausted

-

Invacare

Industries we service

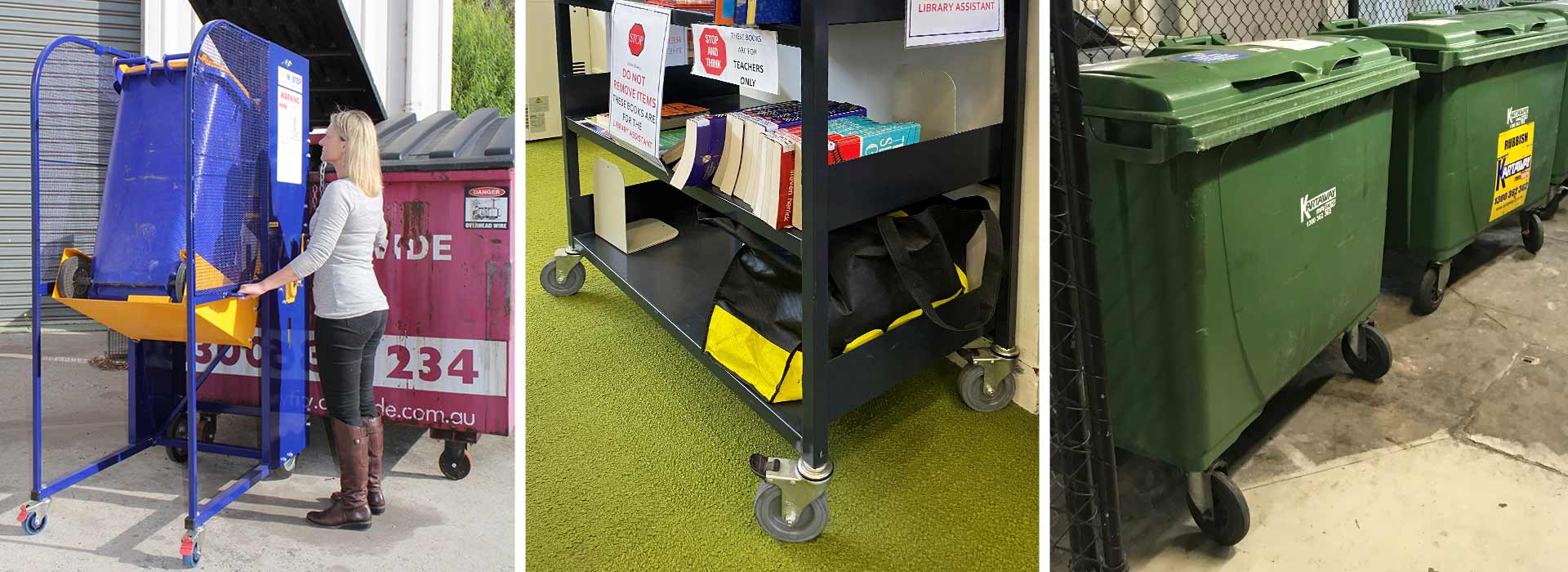

We service a wide range of materials handling equipment, used across industrial, healthcare and commercial businesses Australia wide. Below are examples of equipment serviced within different industries.

Healthcare

We service bed movers, linen trolleys, tugs and bin lifters.

Our technicians need to be quiet, reliable, highly responsive and be compliant with safety standards and hospital procedures and processes. Facility and building departments will hire us under yearly contracts. Mainly preventative maintenance of bed movers and tugs in hospital wards and basement carparks.

Manufacturing / Warehousing

We service powered materials handling equipment, hydraulic machines, electronic actuators, forklifts, walkie stackers, tow-tugs and bin lifters.

Fast response times and onsite repairs are key in the demanding conditions of factories. Operations are characterised by a persistent quest for efficiency and rely on 100% uptime. We mainly provide preventative maintenance to warehouse equipment.

Apartments / housing

Mostly services of tugs (including Zally Incliner tugs) and Sulo skip bins.

This may include fitting bin hitches to 660L or 1100L skip bins for the purpose of towing up and down car park ramps using a powered tow-tug.

Aviation

In the terminal and on the tarmac we maintain tow-tugs, baggage trolleys, stock/retail trolleys and burden carriers.

We can also asses specialised or custom equipment for the purpose of diagnosing faults and making general repairs using OEM parts and components.

Government

Mostly bin lifters and specialised trolleys for government facilities but may include a variety of materials handling equipment that is used in and around office buildings.

We offer customised solutions as a separate service and are engineered.

Construction

Maintaining and repairing bin lifters that are used in the disposal of plastics, metals, rubble into larger skip bins. We also test and tag powered tools and equipment.

Customise trolleys for transporting timber and building supplies over rough terrain can also be engineered to solve a specific problem.

Universities / schools

Castor replacements and trolley repairs.

Refurbishing specialised equipment that would otherwise be replaced before its life-cycle.

Zoos / Convention centres

Specialised environmental equipment and trolleys within a veterinary and post-mortem settings where hygiene and sanitisation are very important.